Dual power automatic transfer switch

product description

RCQ automatic power transfer switch (referred to as switch) is suitable for AC 50HZ, rated working voltage 380V, rated working current 63A~225A dual power supply system, using automatic or manual operation to complete the switch between common power supply and standby power supply.

The switch is mainly used in hospitals, shops, banks, chemical, metallurgy, high-rise buildings, military facilities and other important occasions.

Normal working conditions

◎ Altitude: The altitude of the installation site does not exceed 2000 meters.

◎ Ambient temperature: the upper limit is not higher than +40 ° C, the lower limit is not lower than -5 ° C, and the average value of 24 hours does not exceed +35 ° C.

◎ Atmospheric relative humidity: no more than 50% when the ambient temperature is +40 °C, and higher relative humidity at lower temperatures. Condensation on the surface of the product should be considered in consideration of humidity changes.

◎ There is no danger of explosion of the medium, and the medium does not have enough gas and dust to corrode and destroy the insulation.

◎ There is no significant shaking and shock vibration.

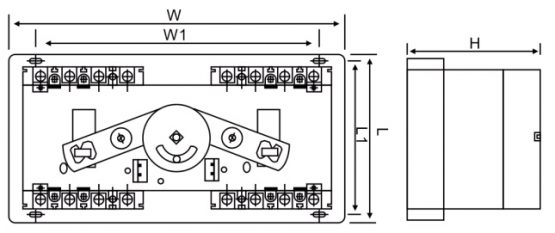

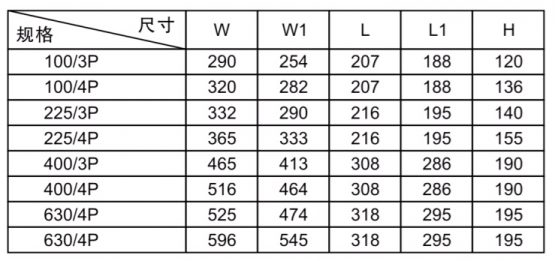

basic structure

The RCQ automatic power switch is mainly composed of a power conversion execution circuit breaker. The switch operation has three status positions for the user to select: common power supply (N), double, and backup power (R).

The switch has the characteristics of small size, light weight, stable operation and convenient use.

Installation and use

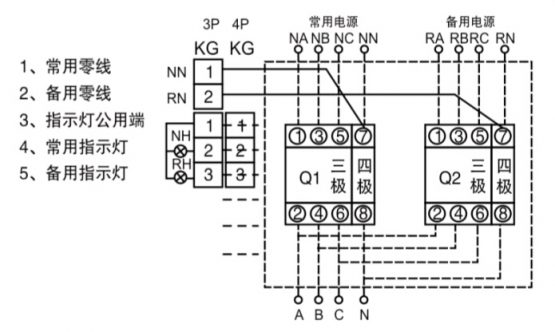

When wiring, the common power supply N should be connected to the common power supply to perform the circuit breaker QN, and the backup power supply R should be connected to the standby power supply to execute the circuit breaker QR. When QN and QR are four-wire circuit breakers, the wiring method is according to the wiring diagram, where QN and QR 1, 3, and 5 are three-phase (A, B, C) incoming ends, and 2, 4, and 6 are three-phase outgoing lines. End, 7 is the zero line (N) incoming end, and 8 is the zero line outgoing end. If the circuit breaker is a three-pole circuit breaker, the neutral line NN of the common power supply (N) and the neutral line NR of the standby power supply (R) must be simultaneously connected to the three-pole dedicated zero line terminal KG. See the wiring diagram for specific operations.

The working power supply of the automatic controller of the dual power switch is taken from the incoming phase A and the neutral N of the circuit breakers QN and QR. If the circuit breaker is a three-pole circuit breaker, the neutral wires NN and NR must be connected. The dedicated wiring zero terminal is in the middle of the two circuit breakers. When the automatic power switch is installed, during the wiring process, do not forget, break or short-circuit the local controller line that was originally connected to the line end of the circuit breaker.

Using method of operation

Manual operation can be used regardless of the voltage of the common power supply and the standby power supply.

When manual operation, the manual-automatic button should be placed in the manual operation position. When the push handle is rotated clockwise to the terminal, the backup power supply performs the circuit breaker QR opening, the common power supply performs the circuit breaker QN closing; when the push handle is counterclockwise When rotating to the terminal, the backup power supply performs the circuit breaker QR closing, and the common power supply performs the circuit breaker QN opening.

In the panel, the power indicator (red), if the light is off, the power supply of the automatic control box is faulty and the switch cannot be operated. After the repair is normal, the manual-automatic button is placed in the automatic position state. If the common power supply is normal, the switch will automatically be put into the normal power supply to perform the circuit breaker QN closing state, and the N power indicator (yellow) in the panel is on; If the common power supply is not normal, the switch will automatically switch to the standby power supply QR, and the standby power R indicator (green) will be on.

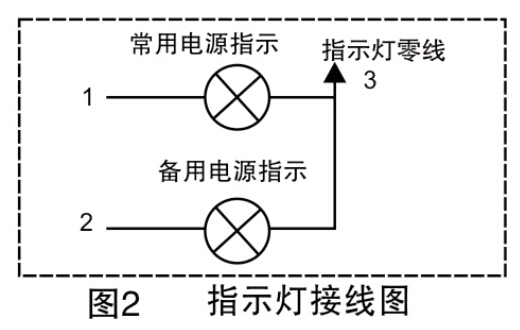

maintain

The switch panel is equipped with two 1A fuses and a three-section terminal block, and the fuse is used as a short-circuit protection for the automatic control box. The terminal block provides active power to the control signal panel to the control panel. The voltage is 220V AC and the current is 15mA. 1 is the common power signal closing indication, and 2 is the standby power signal closing indication. The specific operation can refer to random carrying. The dotted line in the wiring diagram of the control box signal in the wiring diagram.

Warning

1. Do not plug or unplug the controller with power, otherwise it will cause electric shock or product damage.

2. Non-professionals are prohibited from operating or repairing, otherwise it will result in electric shock or product damage.

3. The user of this product does not need to be modified, otherwise it will cause damage to the product.

4. The load capacity must not exceed the rated capacity of the switch, otherwise it will cause the switch to trip or burn out.

5. The neutral line (N) cannot be mistakenly connected to the phase line. The input of the two circuit breakers must be the same. When the three-pole circuit breaker is selected, the common power supply (NN) and the standby power supply (RN) neutral line are simultaneously connected to the terminal block. (KG) Pin 1 (N), otherwise the switch will be damaged. The ground wire should be connected reliably to ensure safe use.

6. Can not be installed directly in the outdoor work, otherwise shorten the service life or cause adverse reactions.

7. It can not be installed directly in the places of flammable, explosive, humid, direct sunlight, high temperature, vibration, impact, etc., otherwise it will shorten the service life or cause the product to burn and explode.

8. It can not be installed directly in the place where there is conductive dust or wire intrusion, otherwise it will lead to product damage or mechanical failure.

9. The requirements in the manual should be met, otherwise the service life will be shortened.